ZOEMIR COSMETICS

Enhancing the value of the cosmetics packaging

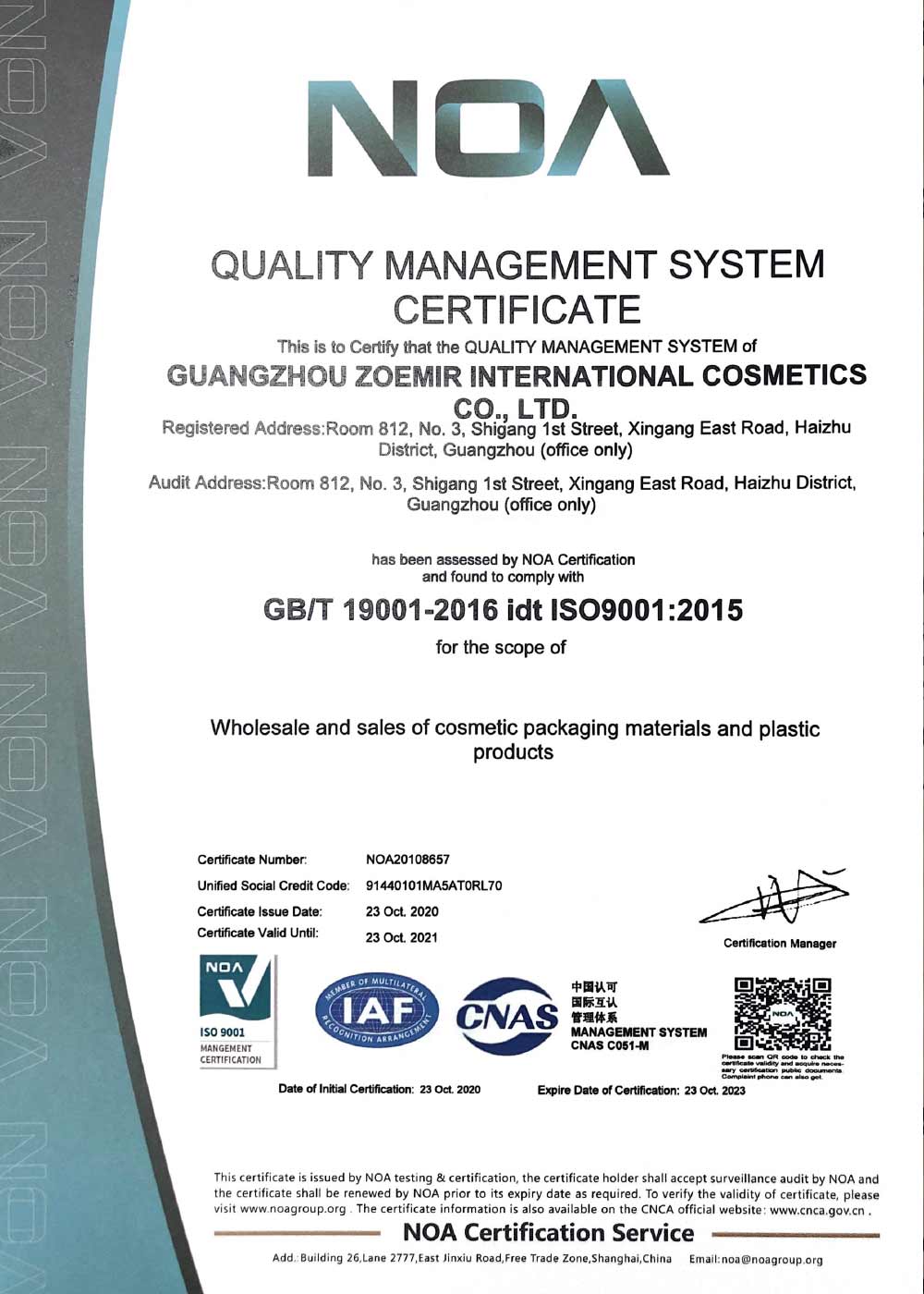

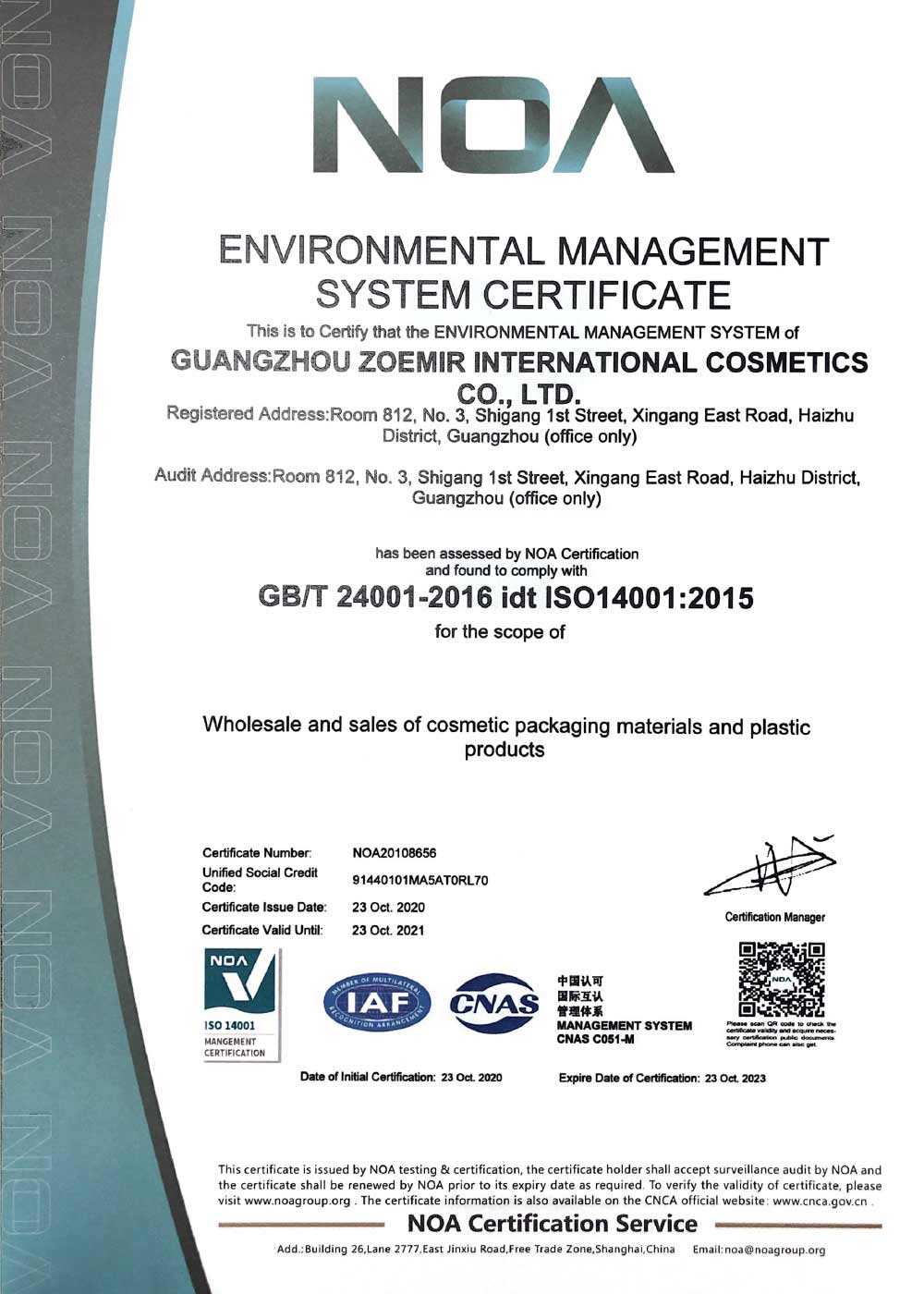

As a reliable partner and certified supplier of the world’s leading beauty business sustain success and to keep quality standards great, we aim to provide clients with comprehensive satisfaction by Continuous quality improvement by processes with validation structures.

In our production process, we have a number of measures to ensure the quality of our products, briefly described as following: